Advanced Water

A company overview

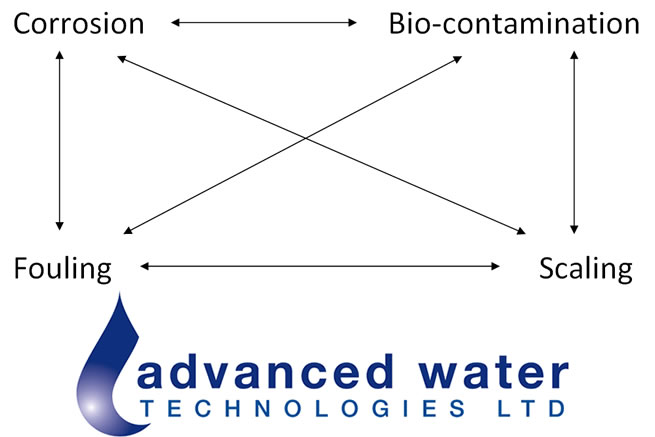

EnquiriesOpen evaporative cooling towers use water to dissipate heat from a process usually via a heat exchanger. However, due to the wide range and various sources of incoming mains top up water to cooling systems a number of problems are quickly arising, these are shown as a matrix below and are all inter related if one factor is present they are all to greater or lesser extent.

Advanced Water Technologies have the expertise to advise on and implement cooling water treatment programs that will eliminate the problems posed by corrosion, scaling, fouling and biocontamination. We can manufacture our own cooling water treatment chemicals at our factory unit thus allowing us to tailor treatment programs to our clients specific needs, enabling cost effective and efficient solutions to be implemented.

Contamination factors are shown as a matrix below and are all inter related, if one factor is present they all are, to greater or lesser extent.

Call our experienced team on:

At Advanced Water Technologies we want to keep you informed and we want to make sure that you have access to all the information you need. You can view all of our accreditations, find out about our services and view important links and legislation information. You can also call or email us by visiting our contact us page.

Scale and its formation are usually associated with hard, untreated make up waters but not always as even soft water systems can form scale from corrosion products. The various scale deposits that form in a system especially in heat exchanges can seriously reduce the effectiveness of the cooling process, even deposit of egg shell thickness will reduce heat transfer very effectively.

Corrosion is damaging to plant components and is the primary cause of expensive plant renewal. For this reason alone it should be minimized however corrosion should be inhibited as it may lead to conditions which encourage the growth of legionella. Again this highlights the inter-related nature of potential problems in cooling systems.

Bio-contamination is probably the most important problem to be overcome in evaporative cooling systems due to the possibility of the presence of legionella bacteria which, if inhaled via sprays and mists, can lead to legionella in humans with potentially fatal results.

Fouling causes a wide range of problems usually, but not always, associated with the presence of corrosion, scaling and bio-contamination. Other factors such as process contamination and environmental debris will also contribute to fouling. A heavily fouled system is far more likely to support bacteria such as legionella and to have further issues with corrosion, scaling and bio-contamination, all of which will compromise the program and reduce its efficiency.

© Advanced Water Technologies