Advanced Water

A company overview

EnquiriesAdvanced Water Technologies is working to be more sustainable and carbon friendly.

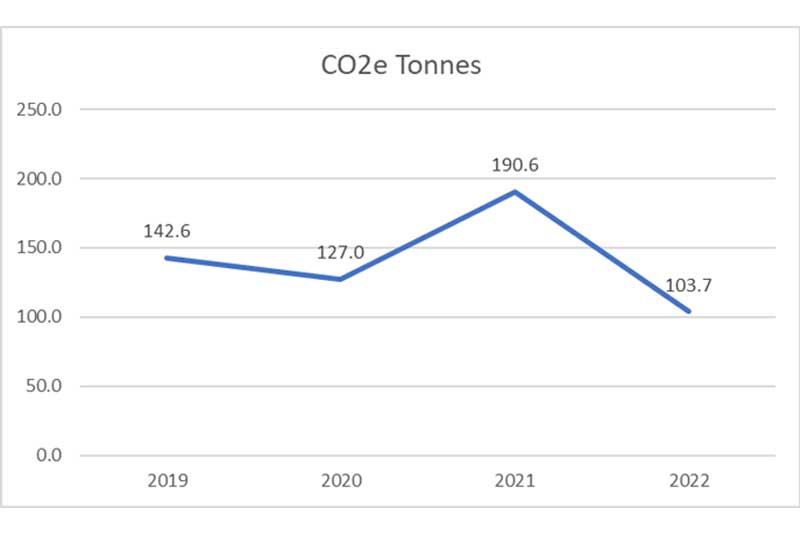

In 2019 Advanced Water Technologies set out a plan to reduce its Carbon Footprint. Initially, reviewing Scope 1 and 2 emissions and targeting those areas it could control.

AWT has implemented several strategic plans to reduce its carbon footprint and in 2021 started to look more closely at Scope 3 emissions, influencing and reducing where possible.

This is against a backdrop of: a pandemic and a plan to increase the size of the business through a recruitment campaign for staff and acquisitions and mergers with other companies.

Vehicles – Accounted for C85% of our GHG emissions year on year. AWT has adjusted the fleet of cars and now has a mix of ULEVs; Petrol Hybrid and Full EVs. A total of 19 vehicles - 4 Hybrid and 15 EVs. In 2022 that will move to 17 EVs. The van fleet, 14, are all have EURO 6 compliant engines.

Electricity – The Head Office and Barlborough Warehouse have Solar PV generation systems, providing 55% of the power to each building – making one unit collectively reliant wholly on solar power.

Drums and Containers – As a chemical distributor, and user, we are moving from traditional 25kg drums to mini reusable IBCs, to deliver products. As we look at Scope 3 emissions, we constantly review how we distribute our products.

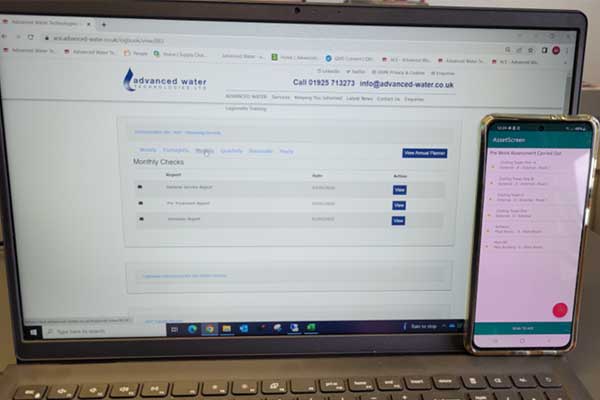

Go-Paperless – The aspiration of all business. AWT introduced a paperless reporting system in 2020 for all its customers, reducing our reliance on traditional carbonized report paper. Representing a reduction of 234kg of C02e annually. This includes 95% e-invoicing to customers.

Christmas Gratuities, go green – AWT annually plant a tree for every active customer. To date that has been more than 1500 trees in partnership with the Yorkshire Dales Millennium Trust. Suporting their initiatives planting in upland areas to help control the flow of water and prevent, in time, flooding down stream.

Waste Disposal – Controlling waste disposal using companies to process waste who demonstrate a recycling achievement of 85% month on month, materials back into the production chains.

Using the mini-IBCs has reduced the amount of unwanted plastic drums, those that do go for waste are recycled back in to the plastic market chain.

© Advanced Water Technologies