Advanced Water

A company overview

EnquiriesWe take great pride in the quality of our service

View all of our full industry registrations

Working in partnership with these companies

Read about our high standards of service

Information and data security standards

Working for Advanced Water Technologies

At Advanced Water Technologies Ltd, we want to make sure that you are fully conversant and compliant with the latest legislation relating to water quality and water safety so that your premises are 100% safe and you are 100% compliant.

Advanced Water

Head Office

2 Webster Court

Carina Place

Gemini Business Park

Warrington

Cheshire

WA5 8WD

Regional Office

Unit 6

Midland Road

Midland Way

Barlborough

Derbyshire

S43 4UL

Southern Office

12 Kent House

Old Bexley Business Park

Bourne Road

Bexley

DA5 1LR

Please complete our online form to send your enquiries.

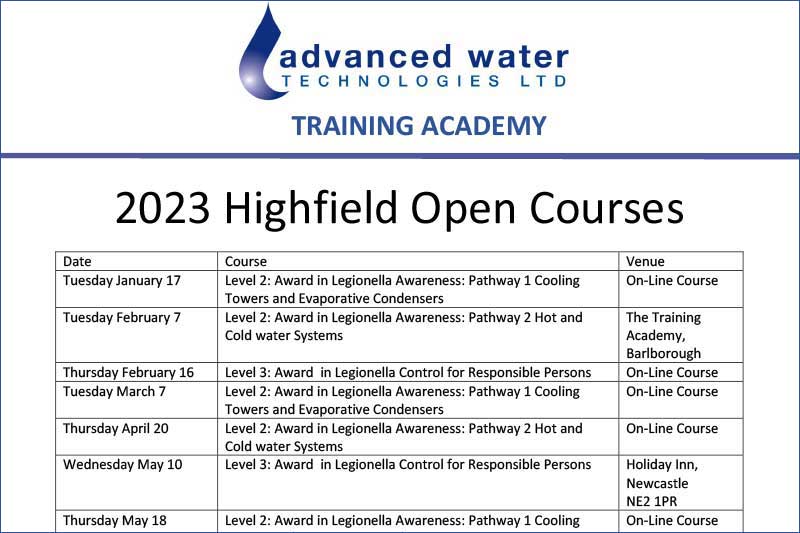

Accredited and Non-Accredited Legionella and Water Treatment / Hygiene Courses.

Contact us for more information about our latest news stories.

Make an Enquiry

Facility Managers, Engineering Managers, QA Managers and Operations Leaders in the food industry. Let us run a quick reality check on your water systems. How confident are you that you can answer “Yes” to the following?

If you cannot confidently answer “Yes” to all of these, your water systems may be putting your operation, compliance, and product safety at risk.

Do you have full control and oversight of your site’s water systems?

Most importantly, act now and speak to us today so we can help you.

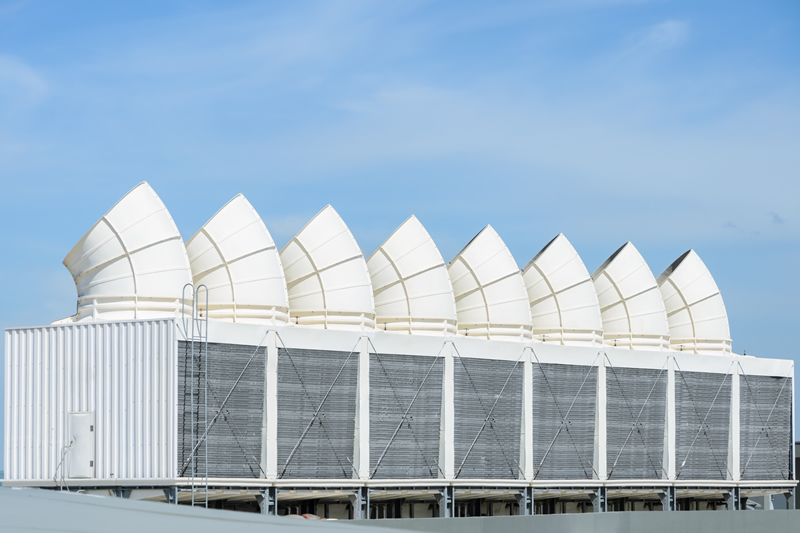

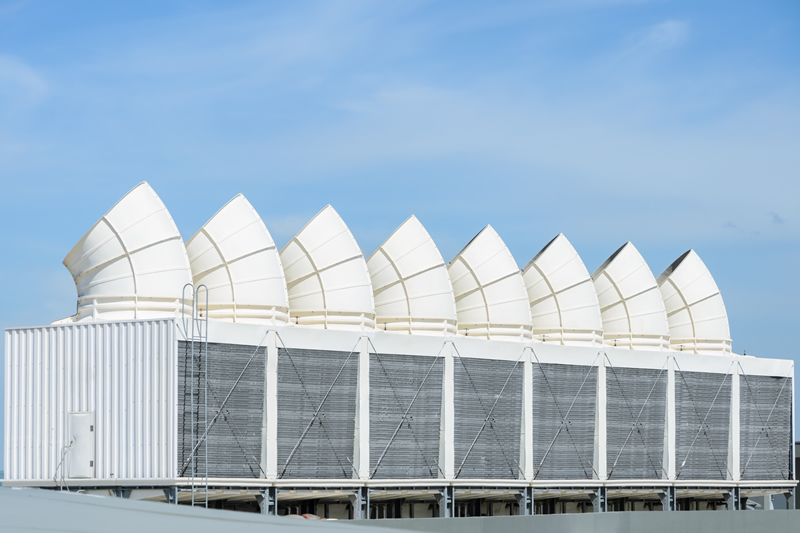

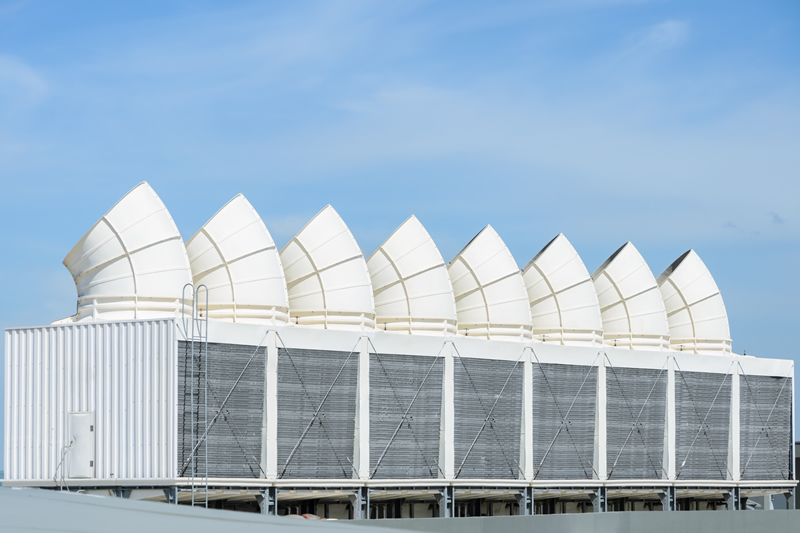

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination #ChlorineDioxide #FacilitiesManagemt #Training #WaterSafety #AWT

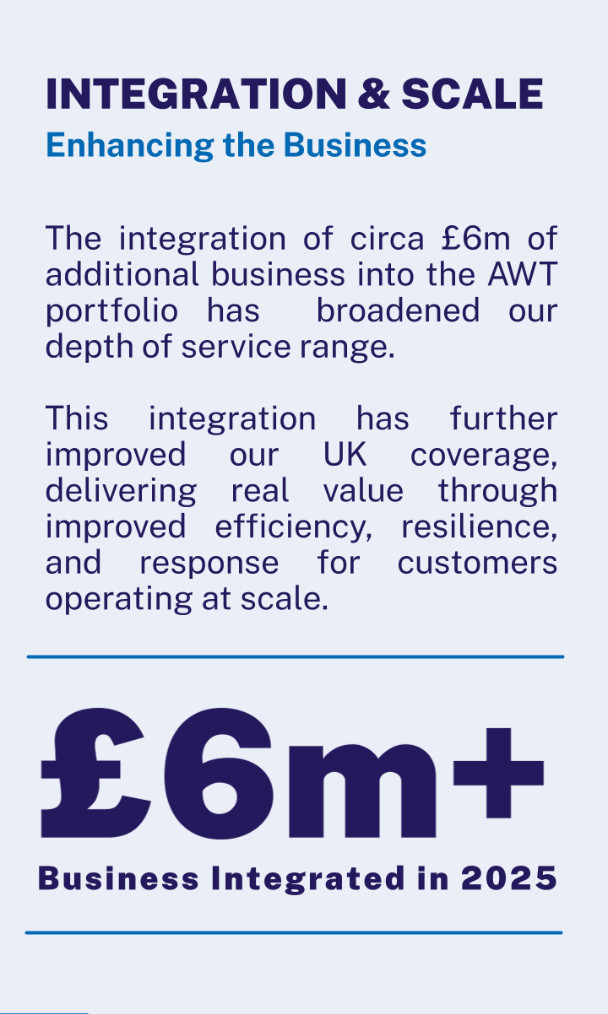

As we look ahead to 2026, we’re excited about what’s to come. The progress we’ve made, the capabilities we continue to build, and our growing national reach are all driven by the dedication, expertise, and commitment of our teams across the UK.

Thank you to everyone who has supported our stakeholders and helped strengthen the business over the past year. With continued investment in people, technology, and innovation, we look forward to delivering even greater value in the year ahead to our new and old customers alike. Follow us to see how we continue to advance water technologies across the UK.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination#ChlorineDioxide #FacilitiesManagemt #Training #WaterSafety #AWT

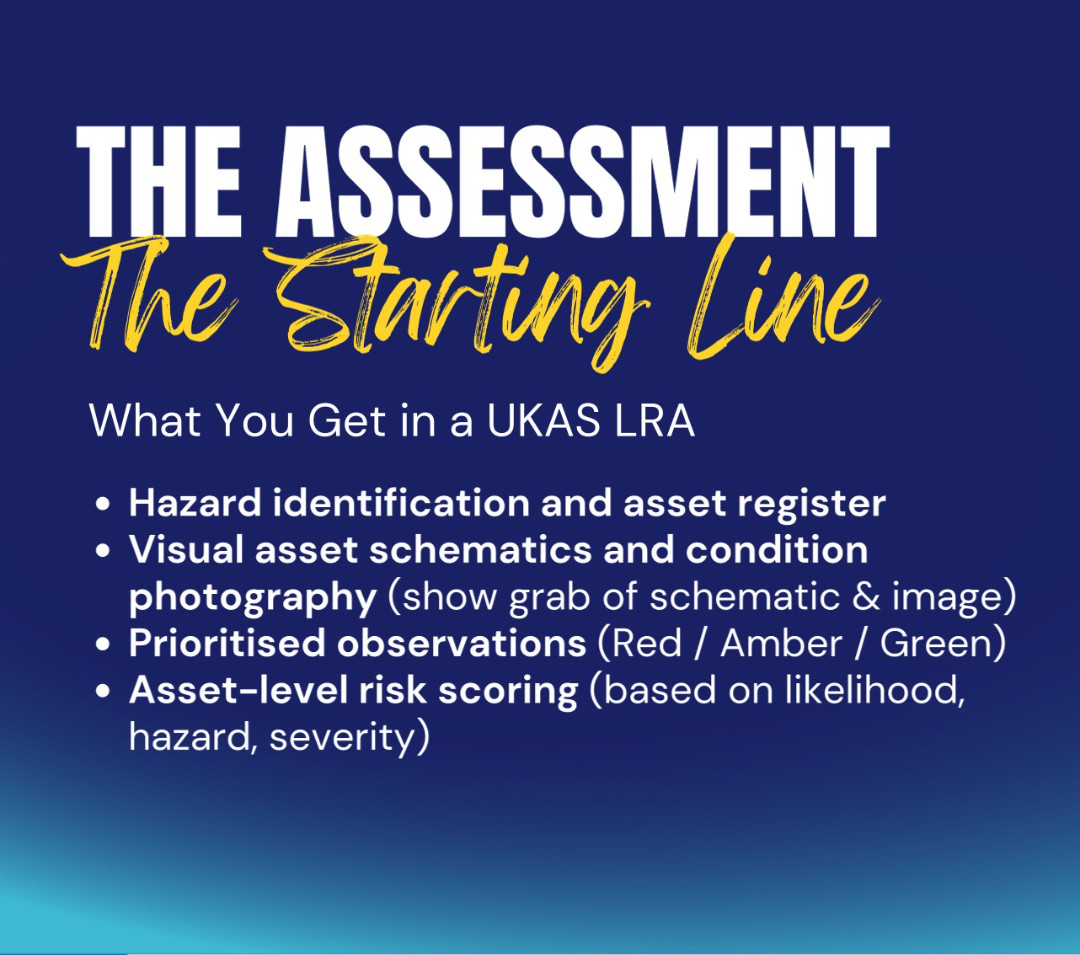

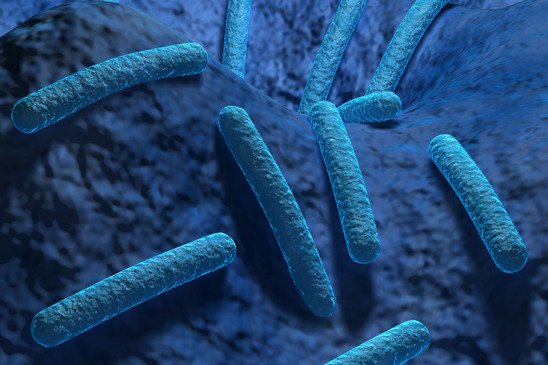

The Legionella Risk Assessment package from AWT brings together multiple technical elements into one coherent view of a site’s water system. Each component, from asset clarity to site-specific monitoring, is developed by specialists to ensure risk is assessed in context, not isolation. It is designed to provide clarity, accuracy and long-term relevance, not just a single moment in time.

The aim of any Legionella Risk Assessment should be to assess and record the extent, condition, design and management of all water systems within a property. It should assess and describe the risk of bacterial contamination by Legionella species, the potential for the bacteria to multiply and the potential for this to infect people with Legionnaires disease. If you want to learn more visit: https://www.advanced-water.co.uk/legionella-risk.

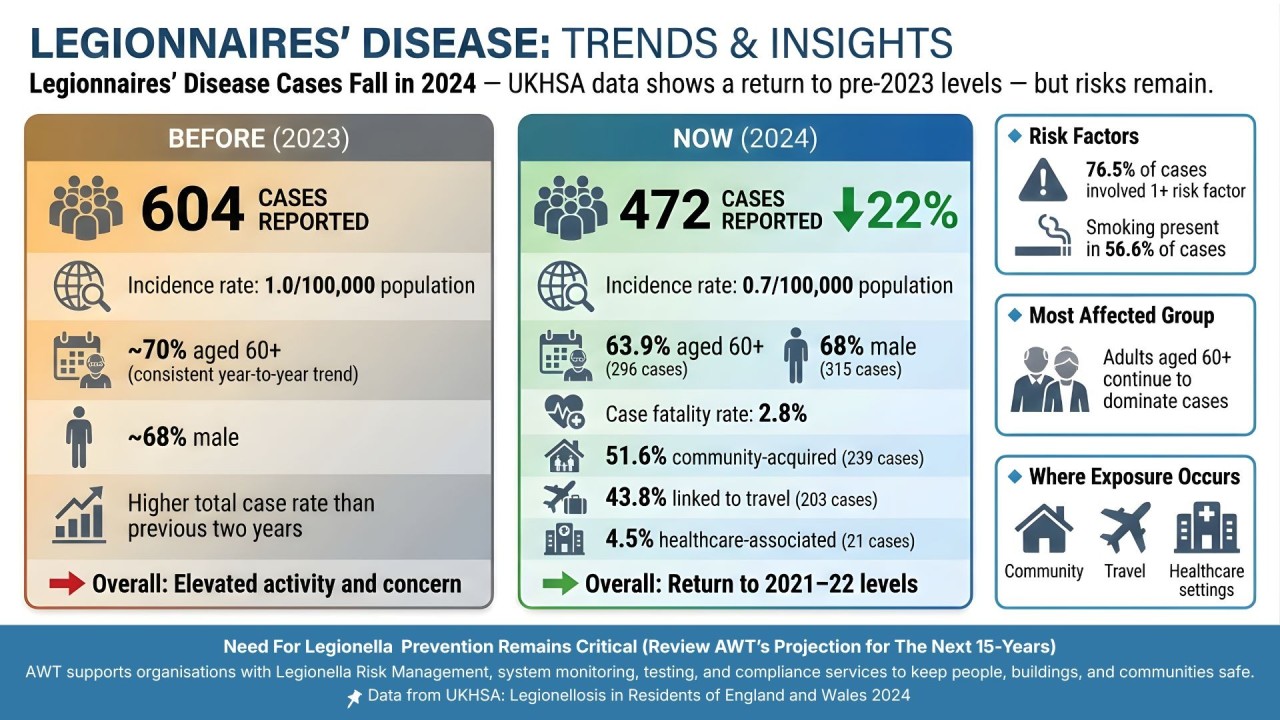

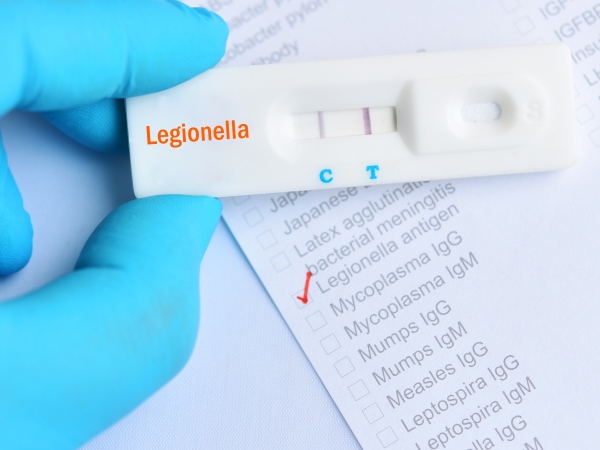

Legionellacontrol.org.uk just posted on 12/12/2025, and the latest UKHSA data shows a clear and encouraging shift. At first glance, the headline figures look positive. But when you step back and look at the full UKHSA study a different pattern emerges: over the past 15 years, cases have risen steadily — with 2023 marking the highest peak on record. The long-term trend is upward, not flat.

That tells us something important: short-term progress doesn’t erase long-term risk.

This improvement does, however, reflect growing awareness, stronger processes, better training, and a real increase in competence across water safety measurements. Businesses, teams, and individuals are taking Legionella risk seriously — and it’s making a visible difference. (And yes, men still feature more heavily in the statistics. Considering they also make up a large portion of roles in engineering, maintenance, HVAC and compliance, it’s probably no surprise.)

Statistics like these are solid proof that prevention work — from accurate risk assessments to good record-keeping and well-managed systems — is not just paperwork. It’s real risk reduction, reflected in real outcomes.

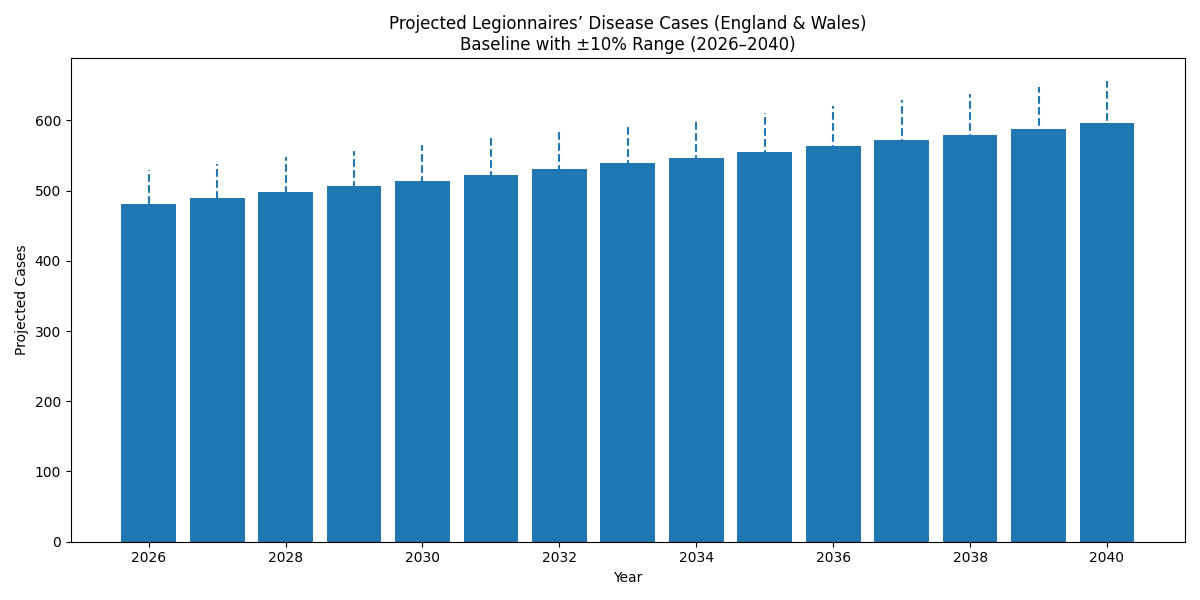

And this is where the bigger picture matters: based on the past 15 years of UKHSA surveillance data, we modelled a projection for the next 15 years. The results show that, unless compliance continues to strengthen and risk management improves, case numbers could keep rising — even if individual years dip up or down. Based on the 15-year trend analysis, projected Legionnaires’ disease cases may reach approximately 593 annually by 2040 (±10%: 534–652), assuming no significant changes in risk management practices.

At AWT, we’re delighted to see the positive movement reflected in 2024. But we’re equally focused on the long-term horizon — helping organisations stay ahead of risk through expert consultancy, risk assessments, safety planning, and water treatment solutions.

Progress is real, and worth celebrating. But prevention is ongoing — and the future depends on what we do next.

We’d like to remind you that AWT is here to support your organisation with the full spectrum of services — from consultancy and risk management to treatment and compliance. If you’d like to learn more about how we can help, or discuss any aspect of this article in more detail, please don’t hesitate to contact us.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination#ChlorineDioxide #FacilitiesManagemt #Training #WaterSafety #AWT

Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. We are taking orders throughout December and will be operational offering products and services as normal. We would like to thank everyone involved with our company including our employees, customers, suppliers and people who have been involved in projects and related activities. We look forward to working with you in 2026.

What makes Advanced Water Technologies different is our people, experts in what we do and passionate about developing long lasting and trusted customer relationships. Our staff are regularly trained and competency checked to ensure we deliver the best water treatments possible. Our customers are pretty special and important to us too. To ensure that we continue to operate at the highest levels of customer service and technical know-how, we undertake an independent evaluation every year.

#SeasonsGreeting #WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination#ChlorineDioxide #FacilitiesManagemt #Training #WaterSafety #AWT

Forward-thinking managers are already planning ahead - and it shows. Two of our 2026 Legionella risk-prevention courses are already fully booked. If you know this skill, knowledge and competence are needed within your business, make sure to secure your spot early. Take a look at our 2026 training calendar and plan ahead with confidence.

Whether you need open courses, company-exclusive sessions or flexible online learning, we’ve got you covered. Our Ofqual-accredited and specialist courses are delivered on-site, remotely or at our Barlborough Training Academy, providing industry-leading competence in Legionella risk management.

Submit your application here or get in touch with us if you have any questions. Visit the full list of course options for 2026 at https://www.advanced-water.co.uk/training-academy

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination #ChlorineDioxide #FacilitiesManagement #Training #AWT

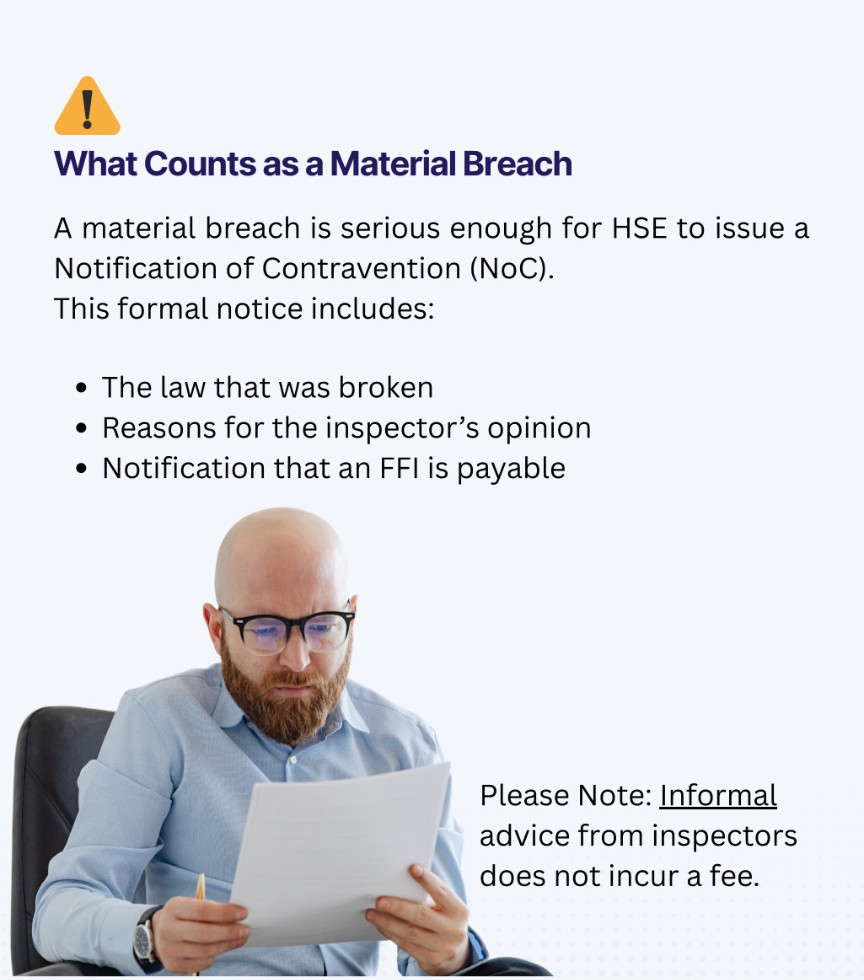

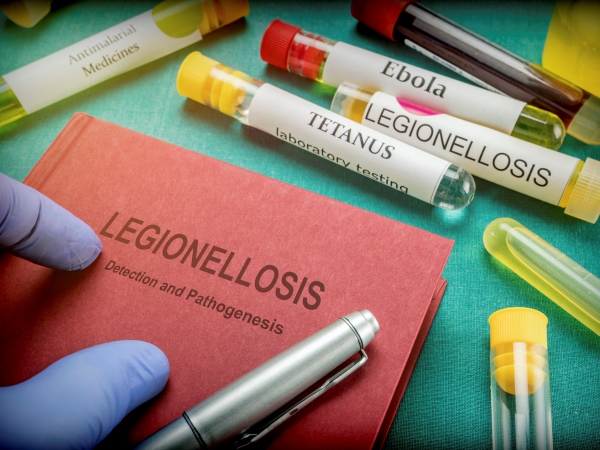

Now, let’s factor in HSE’s Fee for Intervention. Many businesses don’t realise that compliance issues come with an ongoing hourly charge from HSE called hashtag#FFIcosts that can quickly escalate during an investigation. That hourly rate has only increased since the 2023 case study, when FFI was £163/hour. This has increased to £183/hour in 2025. How confident are you in your water safety management? We urge you to don’t leave it to chance, reach out to us today to review your water systems and ensure you’re fully compliant:

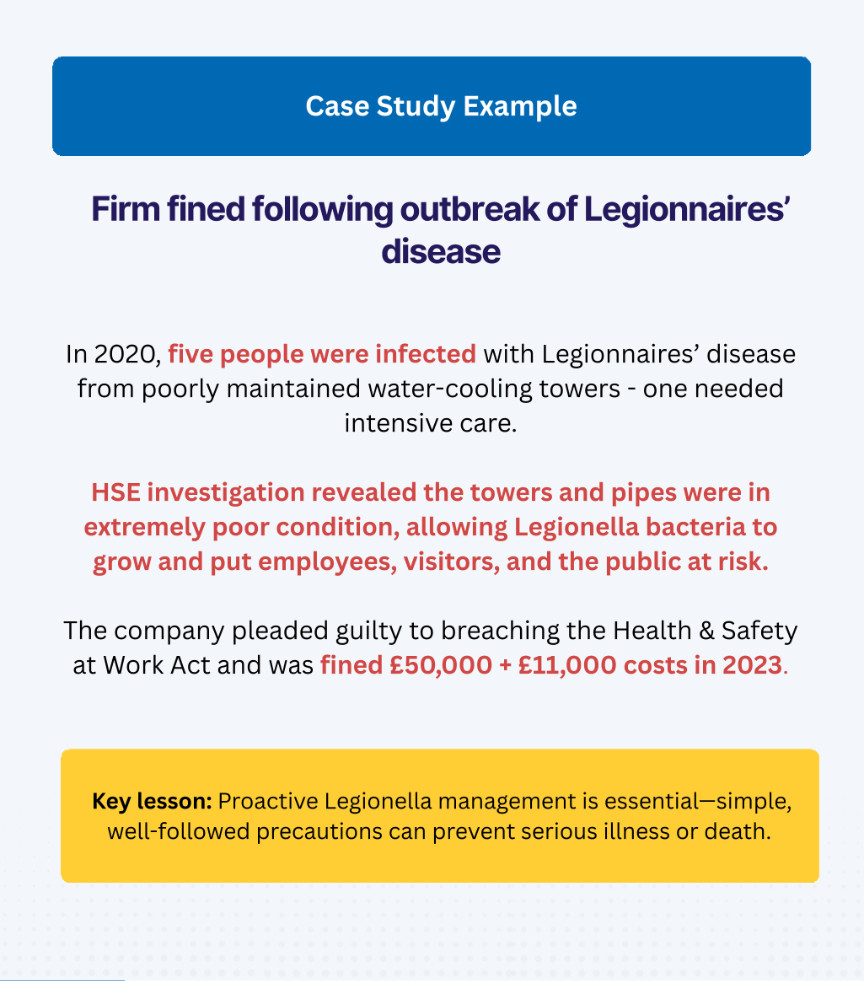

In September 2020, five people (employees and members of the public) contracted Legionnaires' disease from the vicinity of the company's site. One person required intensive care and ventilator support. A Health and Safety Executive (HSE) investigation found that the company's water-cooling towers and pipes were in an "alarmingly poor condition," which allowed the Legionella bacteria to multiply. The condition was described by an HSE principal inspector as the "worst" she had ever seen.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination #ChlorineDioxide #FacilitiesManagement #Training #AWT

Don’t miss this, spaces are filling up. Do you or your team manage cooling towers or evaporative condensers? We have only 10 places remaining on our upcoming Highfield Level 2 Award in Legionella Awareness Course (RQF) Cooling Towers and Evaporative Condensers. To find out more details about the course or to book your spot visit: https://www.advanced-water.co.uk/training-academy. Stay compliant. Protect your team. Prevent Legionnaires' Disease.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination #ChlorineDioxide #FacilitiesManagement #Training #AWT

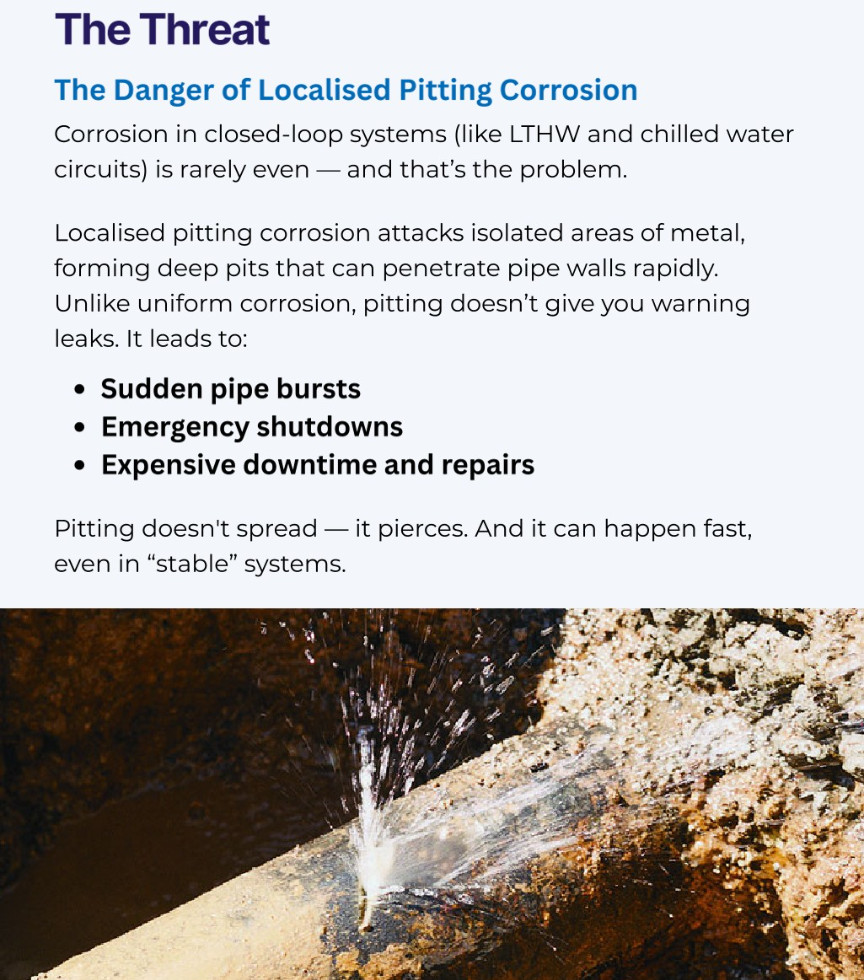

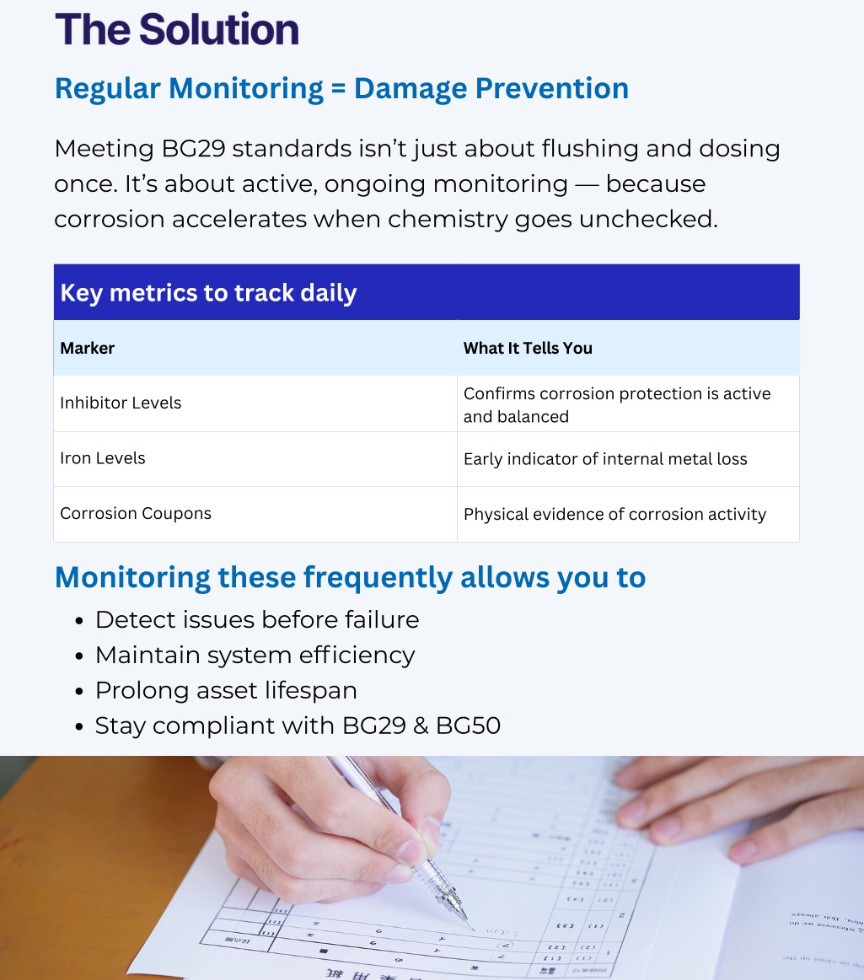

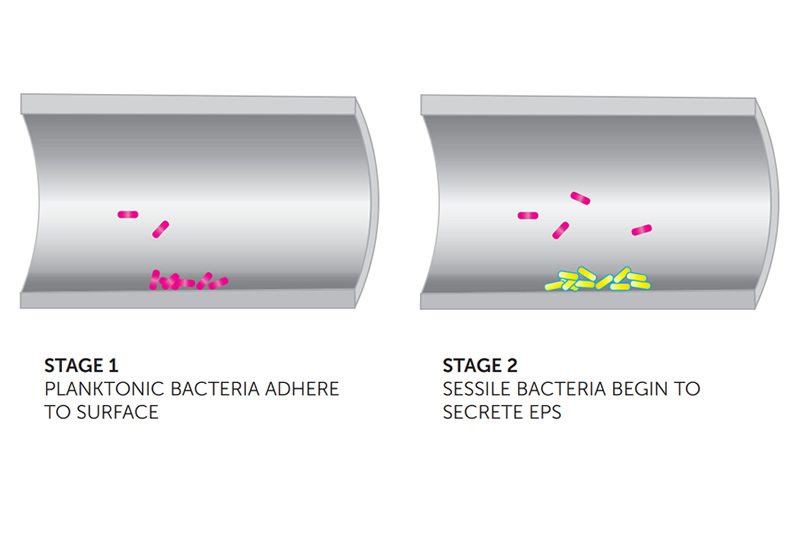

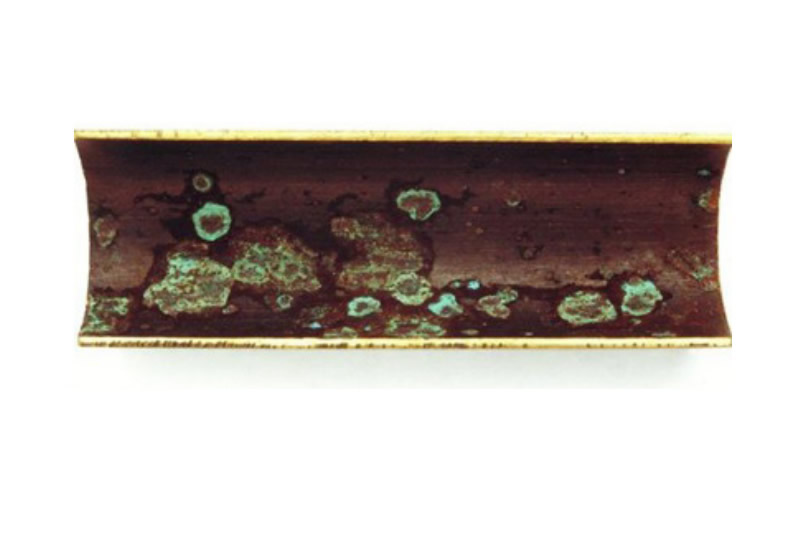

Why Corrosion Rates in Closed Systems Must Be Monitored Daily Regularly? The answer is that it is a silent killer without monitoring. Is your closed system protected, or just waiting to fail? Click the link in the post to speak to a closed system specialist now.

Read our visuals to understand why daily regular monitoring is non-negotiable and how to protect your high-value assets.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination #ChlorineDioxide #FacilitiesManagement #Training #AWT

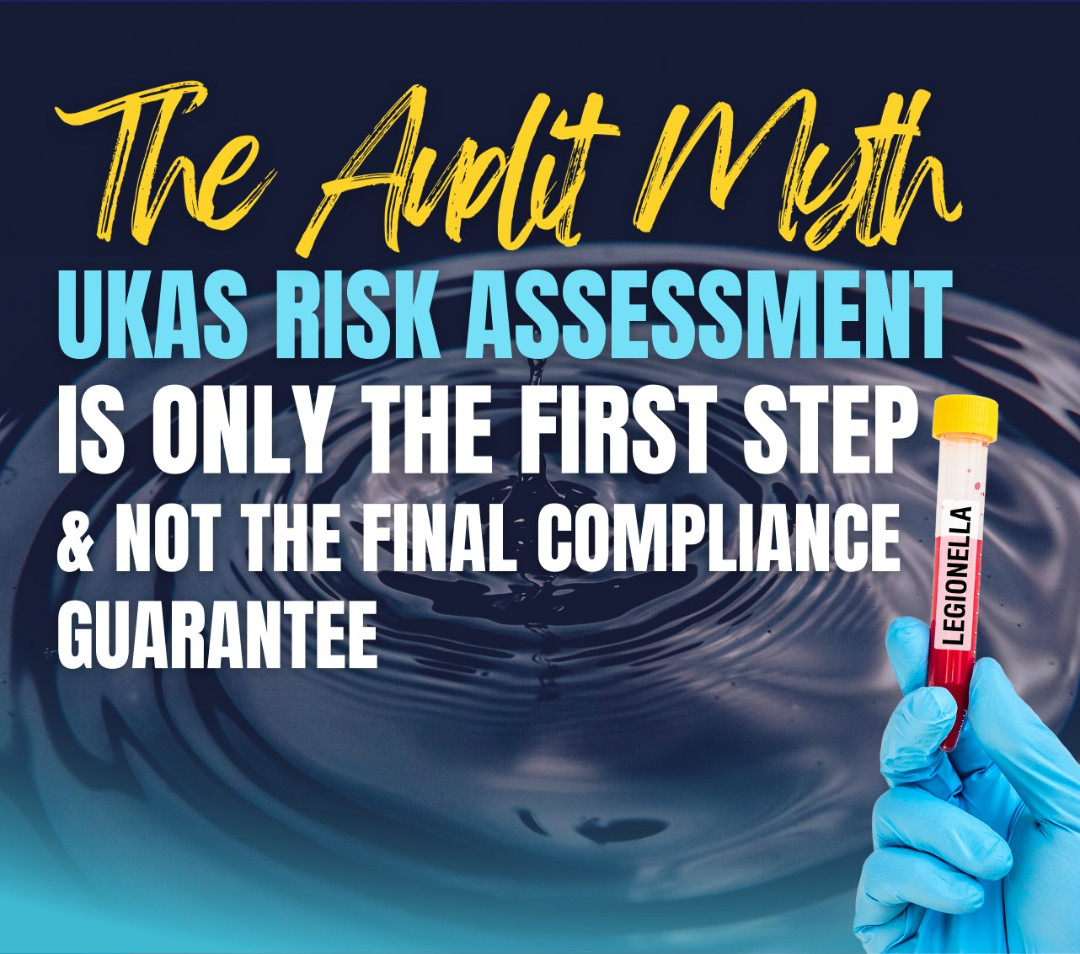

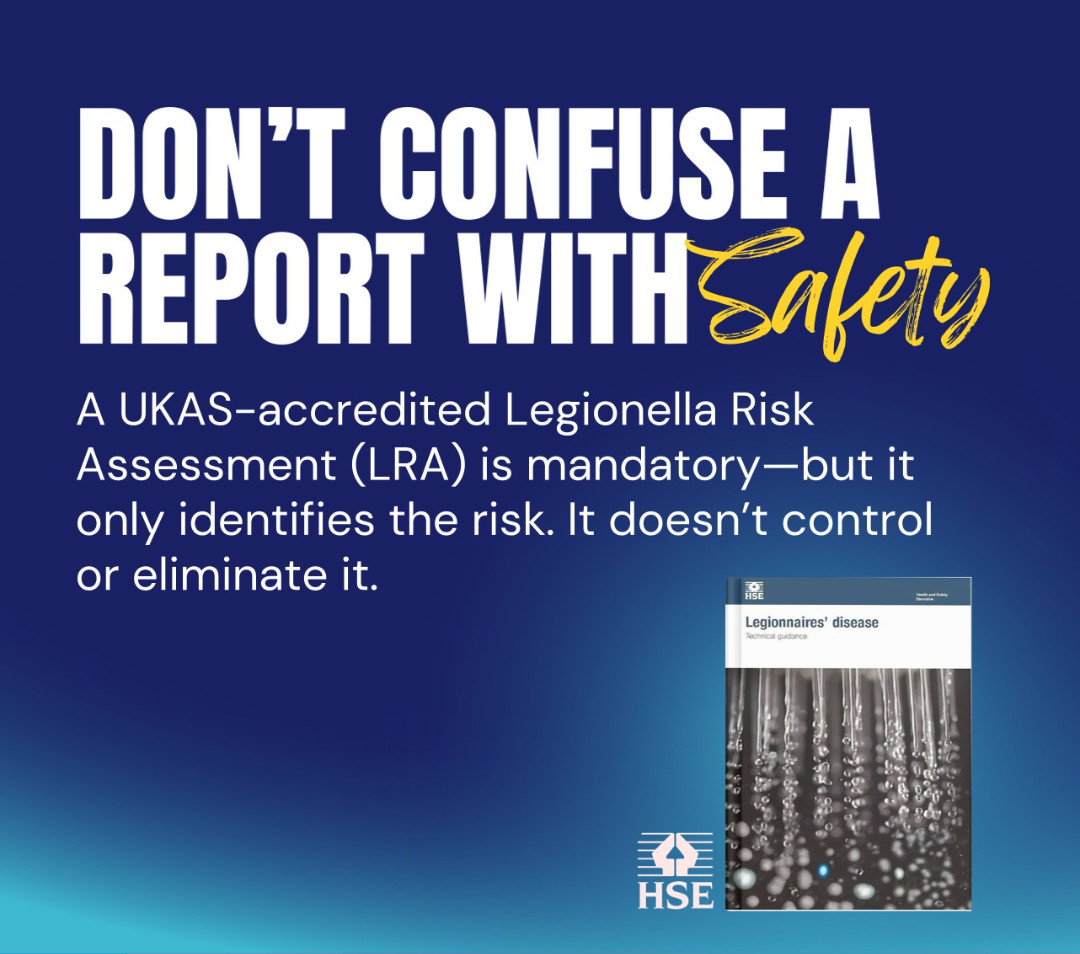

A Legionella Risk Assessment Names The Risk But Does Not Eliminate It

Read our guide to understand the critical difference between the Assessment and the ongoing Control Scheme required by ACOP L8. Don't confuse a report with safety. Full ACOP L8 compliance is an ongoing action.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination #ChlorineDioxide #FacilitiesManagement #Training #AWT

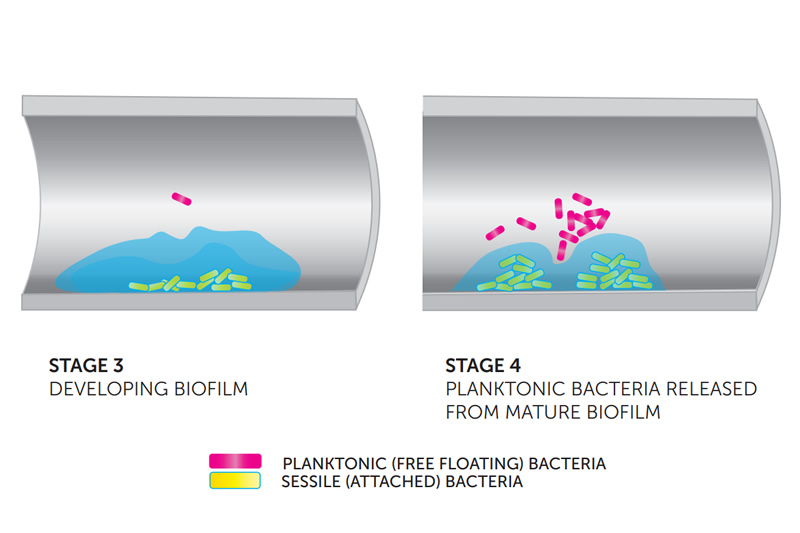

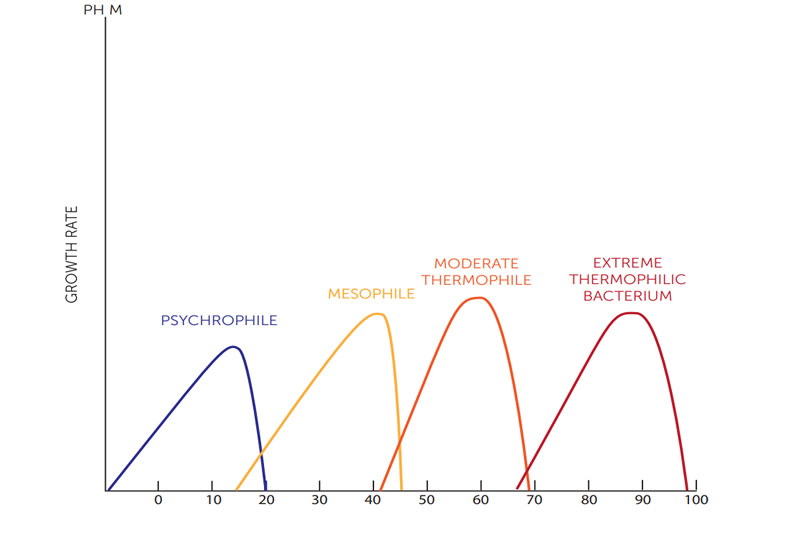

Your process system is probably unique, so why are you using standard, generic treatment chemistry? In complex industrial environments, standard products often fall short, leading to inconsistent results, higher usage, and, ultimately, costly system damage. The visuals below will outline why bespoke chemical programming is an important investment.

Find out more about a custom programme designed for your plant's success and share this with a colleague who manages industrial process water.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination #ChlorineDioxide #FacilitiesManagement #Training #AWT

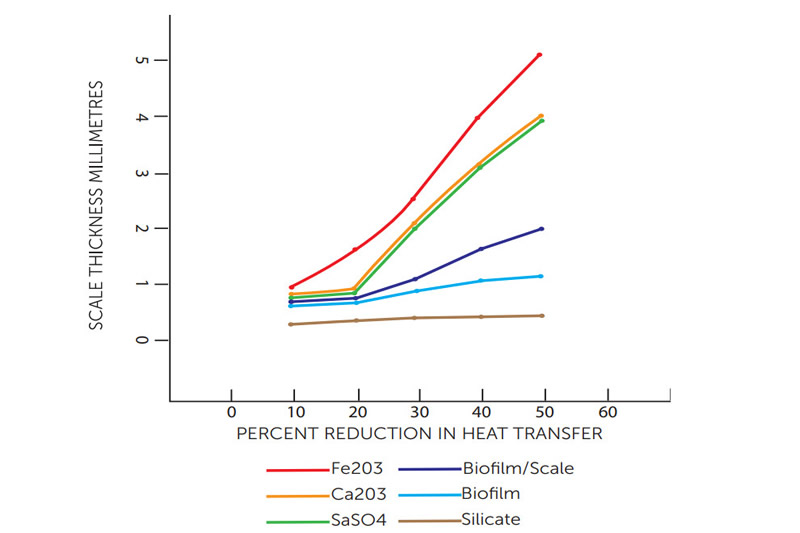

Most facility managers know scale is a problem, but few realise the staggering cost hiding in their boiler system. Just a thin layer of scale drastically reduces heat transfer efficiency, forcing your system to work harder and unnecessarily increasing your fuel costs. We have broken down the risk into three quick checks that every engineer and manager should review today. Swipe through to see the checklist that helps to protect your assets and your P&L.

Don't let scale silently erode your profits. This is a risk that requires your action. Share this with your Facility Manager or Maintenance team.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination #ChlorineDioxide #FacilitiesManagement #Training #AWT

Compliance requires vigilance. In our experience auditing cooling tower systems, we repeatedly see three critical monitoring failures that immediately raise the risk profile and flag potential audit issues. These aren't system failures, they are people failures. Swipe through and check if your current monitoring process is exposed. Monitoring is your first and best line of defence. Don't leave your cooling tower compliance to chance. Ask yourself this: What is the most common monitoring mistake you’ve witnessed in your career?

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination#ChlorineDioxide #FacilitiesManagement #Training #AWT

Don’t miss this Legionella Awareness Course as spaces are filling up. Do you or your team manage cooling towers or evaporative condensers? We have only 10 places remaining on our upcoming Highfield Level 2 Award in Legionella Awareness Course (RQF) Cooling Towers and Evaporative Condensers.

To find out more details about the course or to book your spot visit https://www.advanced-water.co.uk/training-academy. Stay compliant. Protect your team. Prevent Legionnaires' Disease.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination#ChlorineDioxide #FacilitiesManagement #Training #AWT

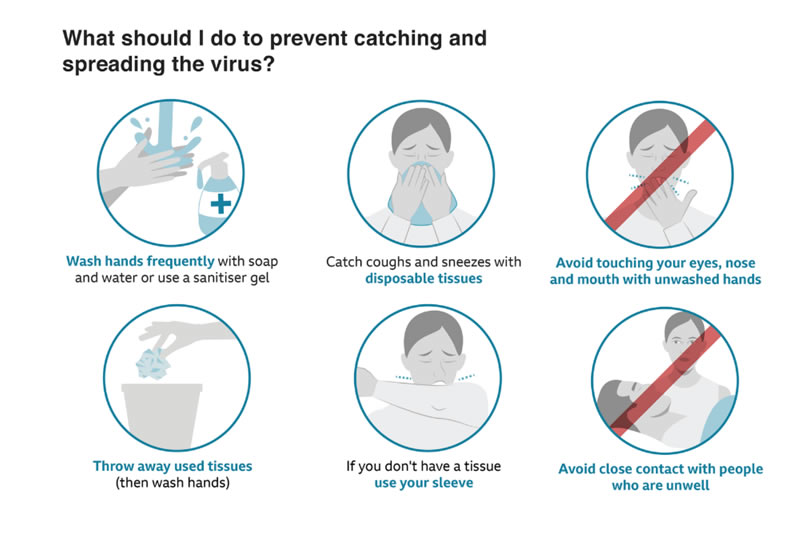

If you think your water systems are due for a review, reach out to us and book a free consultation today. Keeping your water systems safe isn’t just best practice, it’s a regulatory requirement.

Here are a few key times disinfection is necessary:

Regular risk assessments and monitoring are key to knowing when disinfection is needed. A proactive approach protects both building occupants and your business from potential legal and health risks. Visit our website to learn how we can help you stay aligned with UK standards.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site by calling 01925 713273, emailing us at info@advanced-water.co.uk or by visiting our online enquiry form at https://www.advanced-water.co.uk/enquiries.

#WaterSafety #WaterDisinfection #CoolingTowers #WaterTreatment #Legionella #LegionellaControl #Chlorination#ChlorineDioxide #FacilitiesManagement #Training #AWT

Just about two weeks ago, Members of AWT gathered for a fantastic day out at Newbury Racecourse with the AWT Southern Regional team. Organised by our Southern Regional Manager Shane, it was such a great opportunity to connect, celebrate, and recognise the hard work and dedication that everyone contributes to the region.

AWT is grateful to be part of such a committed group of people who always bring their best. A dedicated water treatment and hygiene specialists focused on providing optimum solutions across a vast array of services, chemicals, equipment, risk assessments supported by innovative IT technologies for optimal performance and assured compliance.

#CoolingTowers #WaterTreatment #Chlorination #Legionella #ChlorineDioxide #Training #WaterSafety #AWT

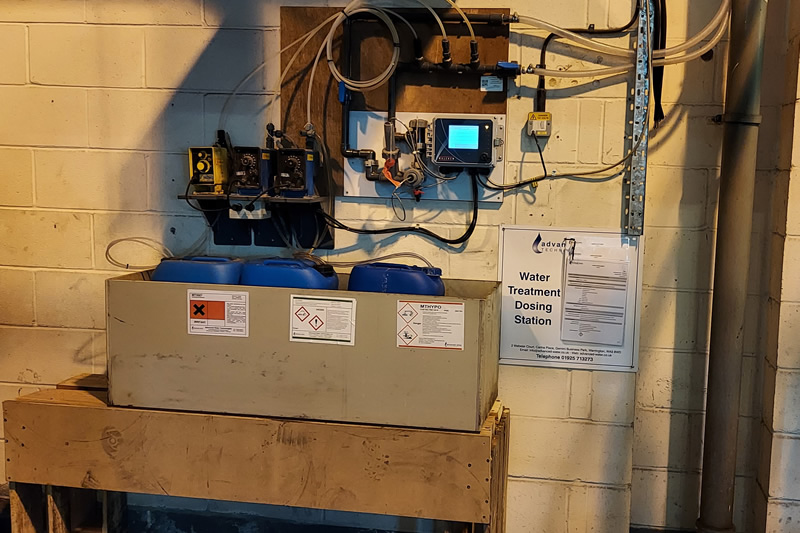

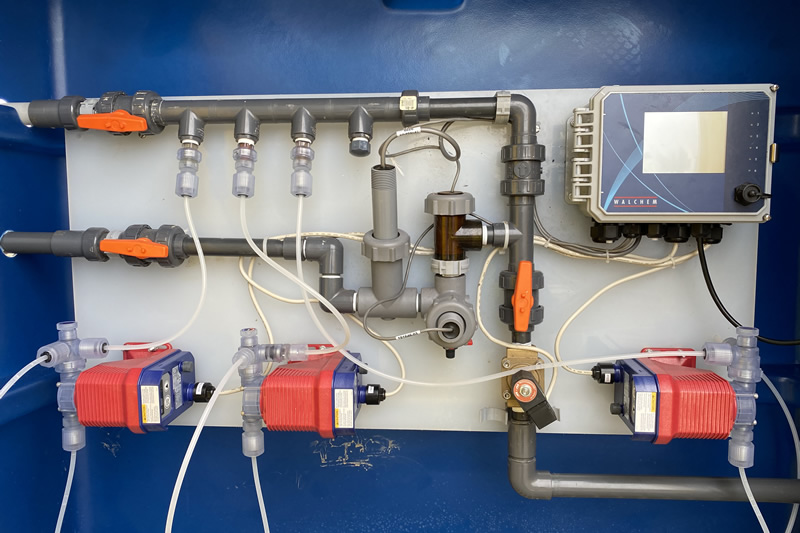

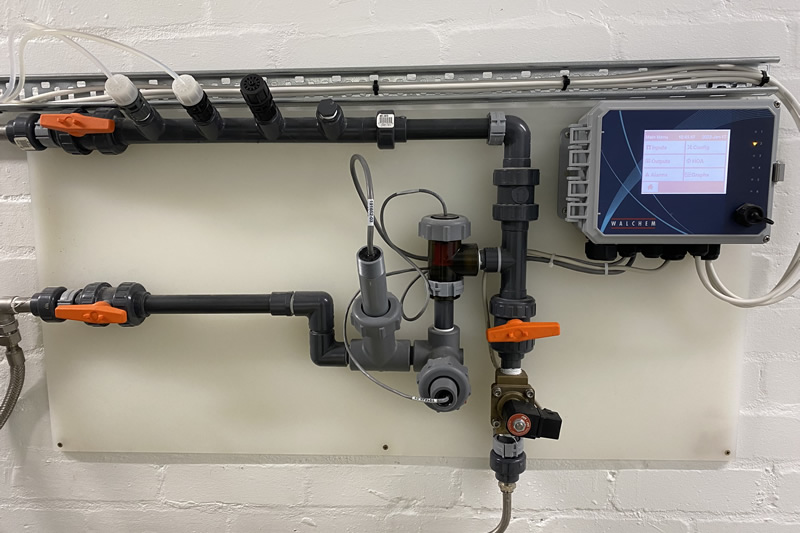

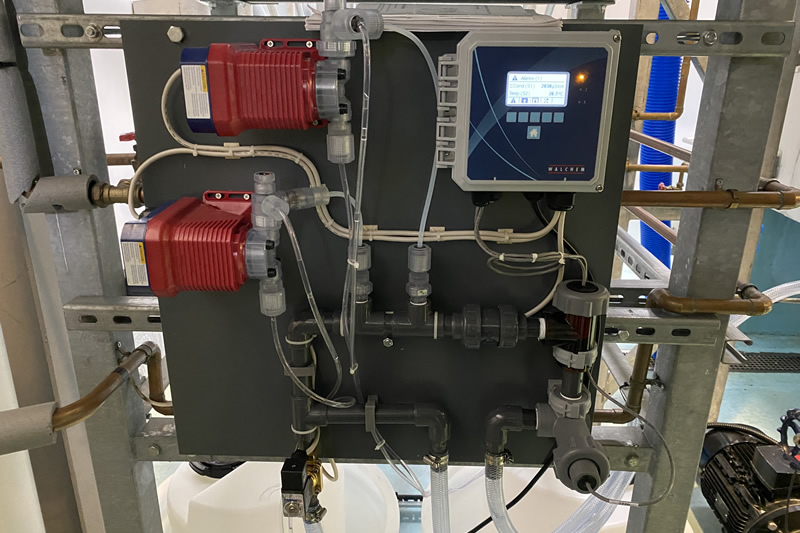

These units were built with free ClO2 analyser for easy readout display and protection mechanisms to prevent overdosing. This has ensured our client maintains compliance with disinfection of potable quality water and reduction in chemical consumption costs.

A recent install we’re proud of. We replaced outdated hashtag#ClO₂ systems at a key client site with state-of-the-art units - now complete with:

What is the outcome? Improved compliance, reduced chemical use, and peace of mind for the client. Safe to say, this marks another successful project delivered by AWT. ClO2 refers to chlorine dioxide, a powerful and fast-acting chemical compound used as a disinfectant, biocide, and sanitizer in various industries, including pulp and paper bleaching, water treatment, and food processing. It is a yellow-green gas that acts as a strong oxidizing agent, but it is also toxic and unstable, requiring careful handling and often on-site generation for safe use.

#CoolingTowers #WaterTreatment #Chlorination #Legionella #ChlorineDioxide #Training #WaterSafety #AWT

Your Legionella risk assessment is a legal obligation and a crucial first step, but it's not the last. The Health and Safety Executive's Approved Code of Practice (ACOP L8) is clear: inadequate training is a major factor in outbreaks of Legionnaires' disease. This is why having a competent and trained team isn't just a good idea - it's a legal necessity. A well-trained team is your most effective way to protect your business from legal, financial, and operational risks.

The Advanced Water Technologies Training Academy is here to build that competence. We offer internationally recognised, Ofqual-accredited courses, including:

With courses already scheduled for 2025 and 2026, there’s no better time to invest in your team. We offer flexible training either at our bespoke training facility Barlborough (Derbyshire), on your site anywhere in the UK, or online, to suit your needs.

We understand it’s not always convenient to travel away from your place of work, this is why each course listed above can be delivered exclusively to your company at your site, or remotely via Teams/Zoom. With up to ten candidates per course, this makes it the most cost-effective way of funding your training needs. To arrange a date *or to discuss the courses we offer, please contact us at training@advanced-water.co.uk. Ready to invest in your team's expertise? Contact us to book your training today.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Big performance in a small footprint? Challenge accepted. At Advanced Water Technologies, we thrive on making the impossible possible. When a client needed chemical dosing and storage for nine condensers - all within a space just 6m x 2.5m. Our team designed and delivered a fully bespoke solution that fit like a glove. We are ready! Take a look at one of our latest installs below and see what’s possible when experience meets innovation.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

In November 2024, HSL Compliance completed the acquisition of industrial water treatment services provider, Advanced Water Technologies. AWT has offices across the UK employing over 80 people. The acquisition significantly enhances HSL's presence in the UK industrial water treatment market being greater scale, increased opportunity for colleagues and enhancing the combined service offered to clients.

The acquisition takes the combined companies headcount to over 600 people. Following the acquisition, Directors Peter Barratt, Mark Gowland and their senior management team remain in charge of the business to ensure continuity of service to clients. HSL Compliance is a risk and compliance leader, specialising in water, hazardous materials, fire safety and associated Health Safety and Environmental services. As health and safety regulations evolve, keeping your people safe and assuring compliance can be a time-consuming challenge. HSL Compliance makes it simple. From inspection and analysis to remediation and ongoing monitoring, you can count on expert guidance and a service that’s tailored to you.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

We would like to take a moment to introduce you to our Southern Regional Team! We’re proud of the incredible service our regional model delivers across the country for our valued clients.

Speaking within the group about what each person specialises in, it was clear that the depth of experience is incredible. Key areas of specialist knowledge include: Effluent, Training, Mechanical Engineering, Closed Systems, Water Hygiene, FMs, Swimming Pools, and so much more!

All of our account managers and regional managers actively visit sites, committed to understand your specific requirements, and are always on hand to help. With regular team meetings held to discuss their experiences and opinions/ideas, the teams are constantly expanding their own knowledge, gathering an ever-growing array of solutions to share with their clients. And the best part of having a close-knit, regional team, local to your site? If your account manager is unavailable for whatever reason, there’s always a colleague nearby to step in and help.

#CoolingTower #WaterTreatment #Chlorination #LegionellaRisk #Training #AWT

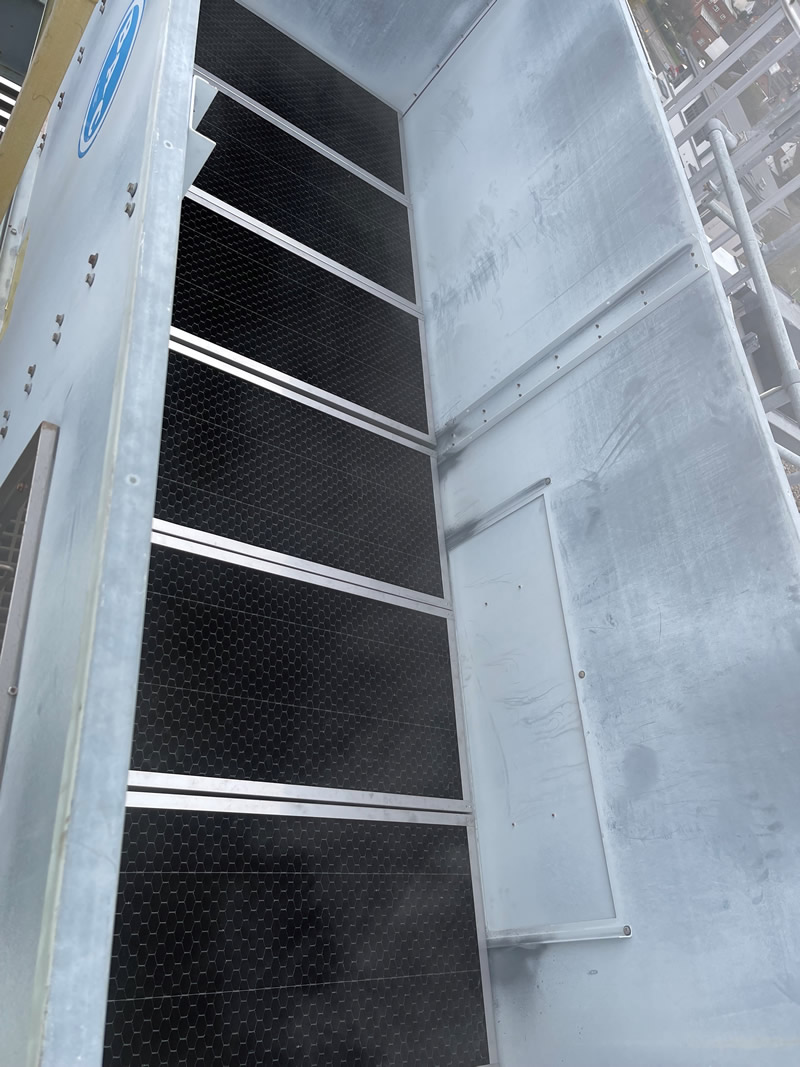

Here at Advanced Water Technologies, we understand that effective cooling tower maintenance is crucial for both operational efficiency and compliance. By using our skilled engineers and disinfection process, we help ensure optimal performance and demonstrate full compliance with regulatory safety standards.

Advanced Water Technologies can also offer GRP (Glass Reinforced Plastic) relining of cooling tower sumps, should corrosion start to be identified. Check out the before and after images. Over time, cooling towers can suffer from surface degradation, leading to corrosion, encouraging bacterial growth. Enhanced GRP relining processes restore the integrity of internal surfaces to a ‘like-new’ condition, improving durability, system hygiene, and extending the asset’s service life.

With decades of experience in water hygiene and cooling tower maintenance, we deliver solutions that satisfy industry standards and exceed our clients' expectations of a water treatment provider. Get in touch today to discuss how we can start supporting your site!

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 8th July 2025 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual-accredited course is aimed at senior people in any organisation and those who manage building water systems, particularly those individuals who are Dutyholders, Responsible Persons or supervisors, to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to highlight the responsibilities and duties of Dutyholders and Responsible Persons and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 3 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF). Photo ID i.e. Passport or driving licence is required to attend the course. A webcam which is on during the whole of the training if it is an on-line course. *Online course only.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

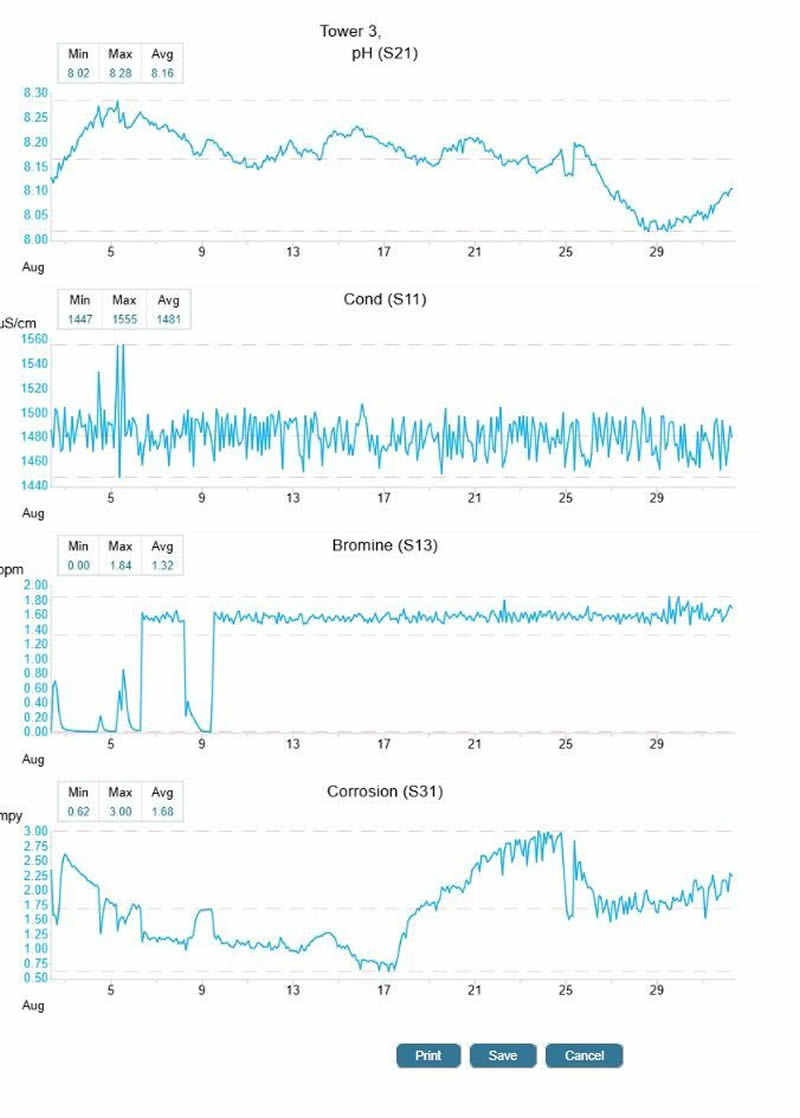

Water treatment is no longer about manual checks and reactive maintenance. With technology like cooling water monitors fitted with SIM card routers, we enable remote access to crucial system data.

What does that mean for our clients?

Smart water management isn’t just the future - it’s happening now. Want to be able to access extensive reports and make changes as needed, securely? We’ve got the technology to ensure you’re always covered and always in the know.

For one of our clients, we added pH, conductivity, bromine and corrosion sensors within their cooling towers and a SIM card to allow for secure remote access. As a result, they saw a reduction in microbiological growth on their dip-slide which essentially reduced their risk of legionella. If there’s an issue, they get a warning instantaneously of levels not being as they should be. On top of that, at ease, our client can extract comprehensive reports to prove compliance for Health and Safety visits, a reduction is risk, stress, and time, all from our solution. Want to know more? Get in contact today.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 8th April 2025 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring hot and cold systems to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

Photo ID i.e. Passport or driving licence is required to attend the course. A webcam which is on during the whole of the training if it is an on-line course. *Online course only.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Advanced Water Technologies are recruiting, a vacancy has arisen for an Environmental Service Technician to join our Yorkshire based team, working out of our Barlborough Office (M1 junction 30). Some experience of the water industry is desirable including water hygiene work, cooling tower and water tank clean and disinfection. For more details contact hr@advanced-water.co.uk.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 17th March 2025 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

Photo ID i.e. Passport or driving licence is required to attend the course. A webcam which is on during the whole of the training if it is an on-line course. *Online course only.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 24th January 2025 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring hot and cold systems to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

Photo ID i.e. Passport or driving licence is required to attend the course. A webcam which is on during the whole of the training if it is an on-line course. *Online course only.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. We are taking orders throughout December and will be operational offering products and services as normal. Our last working day before Christmas will be Monday 23rd December 2024, reopening on Thursday 2nd January 2025. We would like to thank everyone involved with our company including our employees, customers, suppliers and people who have been involved in projects and related activities.

Advanced Water Technologies offer a wide range of water treatment services and management programmes. We have over 200 years of practical experience, comprehensive industry accreditations and a vast knowledge of water treatment products and services. This means we can provide a comprehensive range of water treatment programmes designed to meet customer’s exact needs and conforming to the latest legislation requirements.

We have locations in the North West, East Midlands and the South East delivering flexible water treatment products and services nationally throughout the UK. Covering a range of industrial and commercial sectors, we consistently deliver quality water treatment solutions that are financially, technically and environmentally sustainable. We look forward to working with you in 2025.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

The highly successful Highfield water treatment training courses offered by Advanced Water Technologies have been released for 2025. There are 14 training courses available from January to December 2025 following on from our well received and attended program from 2024. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Our full course schedule for 2025 is presented below:

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Advanced Water Technologies looking to fulfil two roles covering Scotland, North East England and Yorkshire due to rapid growth. £40k to £50k salary dependent on experience plus an excellent bonus scheme. Company car (including electric vehicle options) or car allowance options. Water treatment specialists required, experience with Cooling Towers and Steam Boilers is essential. Send your CV you info@advanced-water.co.uk.co.uk.

At Advanced Water Technologies Ltd our people are our most important asset and we place great importance on professional and personal development to ensure they are best placed to help our customers.

Employee continuity is an essential part of our company. We feel this is essential when offering a quality service, as it means our engineers are able to build an extensive knowledge of your site and the works required to be carried out.

Because we take great pride in the quality of our service, we have developed a loyal team of dedicated specialists who are:

We have locations in the North West, East Midlands and the South East delivering flexible water treatment products and services nationally throughout the UK. Serving a wide range of industries, we strive to continually add value and make a difference to our customers' businesses.

#AWT #Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 23rd January 2025 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual-accredited course is aimed at senior people in any organisation and those who manage building water systems, particularly those individuals who are Dutyholders, Responsible Persons or supervisors, to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to highlight the responsibilities and duties of Dutyholders and Responsible Persons and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease.

Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 3 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

Photo ID i.e. Passport or driving licence is required to attend the course. A webcam which is on during the whole of the training if it is an on-line course. *Online course only.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

This week Advanced Water Technologies have taken delivery of a number of new vehicles. Working in Partnership with TCH leasing, AWT will be replacing its fleet of vans fully over the coming months. Thank you to all TCH for making this a smooth and easy transition. In addition, AWT is working on a project to have some biodiesel tanks installed, that will allow its fleet of vans to be run on an alternative fuel, which will have a significant impact on the C02e outputs. Find out more at https://www.advanced-water.co.uk/latest-news.

#CoolingTower #WaterTreatment #Chlorination #LegionellaRisk #Training #AWT

AWT Training course on 8th November 2024 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

Photo ID i.e. Passport or driving licence is required to attend the course. A webcam which is on during the whole of the training if it is an on-line course. *Online course only.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 3rd October 2024 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring hot and cold systems to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

Photo ID i.e. Passport or driving licence is required for attendance.

A webcam which is on during the whole of the training if it is an on-line course. *Online course only.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Mega Miles Month takes place from the 1st-31st August. We’re asking teams to join in by walking, running, cycling or using a wheelchair or walking aid as much as possible during the month of August. You would each keep track of your miles and get sponsored as you go, contributing towards a team mileage target and fundraising goal. One of the AWT team Simon Ostick attended a recent Colleague Awards event which had Mega Miles as a sponsor with Natalie Bargery as the main contact.

For more information take a look at the Mega Miles Month Fundraising page https://fundraising.makingspace.co.uk/fundraising-group/megamilesmonth

#CoolingTower #WaterTreatment #Chlorination #LegionellaRisk #Training #AWT

AWT Training course on 15th August 2024 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

Photo ID i.e. Passport or driving licence is required for attendance.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Advanced Water Technologies are recruiting, a vacancy has arisen for an Environmental Service Technician to join our Yorkshire based team, working out of our Barlborough Office (M1 junction 30). Some experience of the water industry is desirable including water hygiene work, cooling tower and water tank clean and disinfection. For more details contact mmyers@advanced-water.co.uk.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 3rd July 2024 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring hot and cold systems to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease.

Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF). Photo ID i.e. Passport or driving licence is required for attendance.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 9th May 2024 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF). Photo ID i.e. Passport or driving licence.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 26th April 2024 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring hot and cold systems to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF). Photo ID i.e. Passport or driving licence will be required to attend the course.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

At Advanced Water Technologies, we want to make sure that you are fully conversant and compliant with the latest legislation relating to water quality and water safety so that your premises are 100% safe and you are 100% compliant.

Useful Links Use these links to download the latest HSE information, codes of practice and guidance on workplace health and safety issues. To download the latest HSE recommendations, codes of practice and guidance on workplace health and safety issues, simply click on the relevant hyperlinks on this page https://www.advanced-water.co.uk/keeping-you-informed

Water sources and potential Pseudomonas aeruginosa contamination of taps and water systems - Advice for augmented care unit:Pseudomonas aeruginosa

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Why do you need wastewater treatment? Without effective wastewater treatment your waste water will remain contaminated, meaning you will experience higher running costs (including water and disposal), efficiency problems and of course possible environmental problems. Find out more about our waste water treatment at https://www.advanced-water.co.uk/waste-water-treatment

Wastewater in the UK is treated in three main ways:

Want to discuss this service further? Call our experienced team on Call 01925 713273. At Advanced Water Technologies we want to keep you informed and we want to make sure that you have access to all the information you need. You can view all of our accreditations, find out about our services and view important links and legislation information. You can also call or email us by visiting our contact us page.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

AWT Training course on 1st February 2024 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF). Photo ID i.e. Passport or driving licence will be required to attend the course. A webcam which is on during the whole of the training if it is an on-line course. *Online courses only

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Season’s greetings from all of us and we wish you a Merry Christmas and a Happy New Year. We are taking orders throughout December and will be operational offering products and services as normal. Our last working day before Christmas will be Friday 22nd December 2023, reopening on Tuesday 2nd January 2024. We would like to thank everyone involved with our company including our employees, customers, suppliers and people who have been involved in projects and related activities.

Advanced Water Technologies offer a wide range of water treatment services and management programmes. We have over 200 years of practical experience, comprehensive industry accreditations and a vast knowledge of water treatment products and services. This means we can provide a comprehensive range of water treatment programmes designed to meet customer’s exact needs and conforming to the latest legislation requirements.

We have locations in the North West, East Midlands and the South East delivering flexible water treatment products and services nationally throughout the UK. Covering a range of industrial and commercial sectors, we consistently deliver quality water treatment solutions that are financially, technically and environmentally sustainable. We look forward to working with you in 2024.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Once again Advanced Water technologies has chosen to support Earthly.org (Earthly | Invest in nature) by investing in Nature projects here in the UK, Seaweed Farming in Cornwall and Tree sponsorship in Central Scotland.

These, we considered as worthwhile projects, one that will benefit the environment through high volume carbon absorption - seaweed, but it has additional benefits across many industry sectors, and tree planting in Central Scotland that is one part of a complex mosaic landscape of peatlands, ancient woodland and degraded wildflower meadows. Through holistic restoration of the project area, the aim is to turn the area into a thriving landscape with active ecosystem services and provide a haven for biodiversity.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

The Health and Safety Committee (HSC) Approved Code of Practice (ACOP L8) Fourth Edition places particular importance on the training of personnel at all levels within a company. The need for training is explained in paragraph 50 of the Approved Code of Practice L8, which states: “Inadequate management, lack of training and poor communication are all contributory factors in outbreaks of legionnaires’ disease. It is therefore important that those people involved in assessing risk and applying precautions are competent, trained and aware of their responsibilities”. You can see the full list of courses at https://www.advanced-water.co.uk/training-academy

It is seen that those individuals having active roles in the safe management of water need to have the correct level of knowledge and understanding to carry out their roles and responsibilities adequately. The Advanced Water Technologies Training Academy therefore offers a wide range of training through its fully accredited Ofqual courses, as well as non-accredited courses, online toolbox courses, seminars and webinars. This wide and varied range helps cater for all levels of business requirements, as well as providing flexible learning settings to suit each individual attendee.

Advanced Water Technologies Training Academy offers a wide range of targeted courses.

AWT have various courses currently being offered across the UK by Advanced Water Technologies Training Academy; all being delivered by our highly experienced subject-matter experts:

The Advanced Water Technologies Training Academy Can deliver these courses where and when you want them. We understand it’s not always convenient to travel away from your place of work, this is why each course listed above can be delivered exclusively to your company at your site, or remotely via Teams/Zoom. With up to ten candidates per course this makes it the most cost effective way of funding your training needs. To arrange a date, please contact us at training@advanced-water.co.uk

If you do have a number of candidates wishing to take any of the courses the Training Academy operates Open Courses; where you can join with other candidates from other companies/organisations. Open Courses are delivered at either our Barlborough Training Academy venue or remotely via Teams/Zoom. Please see the booking section for available dates and booking form.

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Advanced Water Technologies are pleased to announce the successful acquisition of SPES Water Compliance, Cannock. A warm welcome is offered to all the SPES staff who are joining the ‘AWT family’, and that is extended to all SPES clients.

This signals a positive move for the future for both SPES and AWT, strengthening the range of services and capabilities that can be offered to all of our combined clients. Additionally, it provides an established base for all of our staff to operate from in the Midlands region. Through expansion and acquisition AWT now has offices located in Warrington, Barlborough, Cannock and Bexley with teams of Sales and Account Managers, and Service Technicians working from each. With warehousing and distribution focused at Barlborough and Warrington.

AWT can assist you with all your Water Treatment needs including Legionella Control in domestic water systems, Evaporative Cooling Systems, Steam Boilers, Heating and Chilled water systems, mains water and building chlorination, training, and other process water systems of your business, for more information www.advanced-water.co.uk.

#Cooling #Tower #Water #Treatment #Steam #Boilers #Chlorination #Legionella #Training #AWT

Advanced Water Technologies have worked closely with one of their long standing clients to improve, and develop, a safer and more efficient dosing system that is linked to their Steam Boilers, which further provides for a greater level of control in their plant and equipment. Contact Advanced Water Technologies to see how we can help you with your plant and equipment.

#Cooling #Tower #Water #Treatment #Steam #Boilers #Chlorination #Legionella #Training #AWT

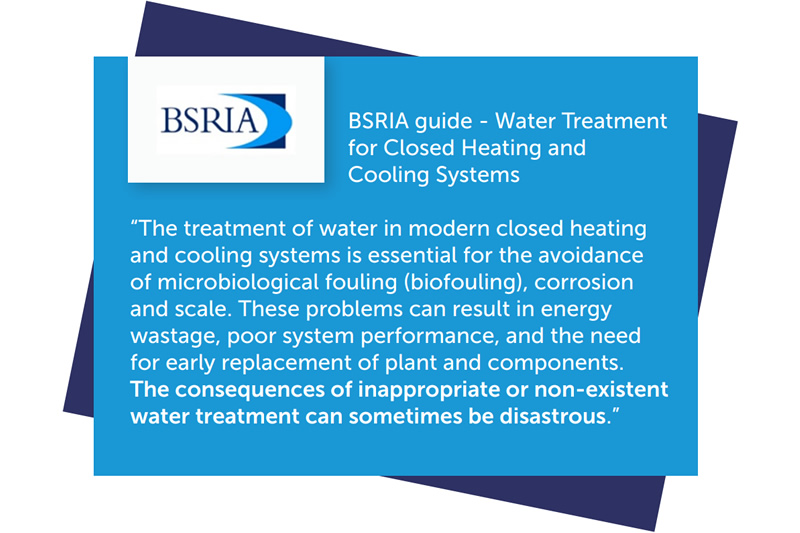

Why do you need a closed system treatment? Without effective water treatment, your closed system for central heating and/or air conditioning can suffer from corrosion, scale formulation, fouling and microbiological activity.

Without effective water treatment, your closed system for central heating and/or air conditioning can suffer from:

These four key factors reduce efficiency, put your system at risk, shorten plant life, and waste energy, chemicals and water charges. It’s a well-known fact that poor control of your closed system can not only put your processes at risk, but can also squander £1,000s in wasted energy, chemicals and water charges.

Welcome to the AWT solution

At Advanced Water Technologies, we have developed a comprehensive closed system treatment programme for effective management, improved performance and to keep your system operating safely and efficiently. These services include:

Because we are compliant with the latest legislation and regulations, particularly in the areas of health, safety and the environment, you can be sure that the solution we deliver will be high quality, reliable, cost effective and tailored to meet your exact requirements.

Chemicals we use in our cooling system treatment

#Cooling #Tower #Water #Treatment #Chlorination #Legionella #Training #AWT

Service Technicians undergo Cooling Tower Training, undertaking the Highfield Level 2 training package, along with practical sessions on cooling water testing at the Advanced Water Technologies Training Academy, Barlborough, improving and consolidating knowledge. This was a recent well attended course provided by AWT.

Want to discuss this service further? Call our experienced team on 01925 713273. At Advanced Water Technologies we want to keep you informed and we want to make sure that you have access to all the information you need. You can view all of our accreditations, find out about our services and view important links and legislation information. You can also call or email us by visiting our contact us page.

#AdvancedWaterTechnologies #WasteWaterTreatment #MetalworkingFluidsTreatment #WaterHygieneTreatment #SteamBoilerWaterTreatment #PaintBoothTreatment #LegionellaRiskAssessment #TrainingAcademy #CoolingTowerWaterTreatment #ClosedSystemTreatment #ChlorinationTreatment #WaterTreatmentChemicals

Advanced Water Technologies invests in new vans and a new look. After 21 years of trading Advanced Water Technologies have adopted a new logo and are starting a rebranding process. We present three of six new vans showing the new look Advanced Water Technologies logo.

Want to discuss this service further? Call our experienced team on 01925 713273. At Advanced Water Technologies we want to keep you informed and we want to make sure that you have access to all the information you need. You can view all of our accreditations, find out about our services and view important links and legislation information. You can also call or email us by visiting our contact us page.

#AdvancedWaterTechnologies #WasteWaterTreatment #MetalworkingFluidsTreatment #WaterHygieneTreatment #SteamBoilerWaterTreatment #PaintBoothTreatment #LegionellaRiskAssessment #TrainingAcademy #CoolingTowerWaterTreatment #ClosedSystemTreatment #ChlorinationTreatment #WaterTreatmentChemicals

Cleaning and Chlorination of water systems is essential to control water hygiene. Different water systems require different treatment and Advanced Water Technologies are experts in the disinfection of all types of water systems from new mains supplies to water storage tanks. Advanced Water Technologies uses directly employed, highly trained staff with relevant qualifications, such as the "Water Hygiene Blue Card", to ensure you have the confidence in our services. Find out more at https://www.advanced-water.co.uk/chlorination-treatment

Want to discuss this service further? Call our experienced team on 01925 713273. At Advanced Water Technologies we want to keep you informed and we want to make sure that you have access to all the information you need. You can view all of our accreditations, find out about our services and view important links and legislation information. You can also call or email us by visiting our contact us page.

#Legionella #Training #AWT

On Monday 23rd January 2023, the Home Office laid out the Control of Explosives Precursors and Poisons Regulations 2023 which make a number of additions to the Poisons Act to strengthen the framework in place for controlling the use of precursors and poisons.

These new measures will come into force on 1st October 2023 and include new requirements for reporting suspicious transactions, additional obligations on online marketplaces, and new requirements for businesses to pass information about restricted chemicals along the supply chain.

Advanced Water Technologies Ltd have taken steps with our suppliers but we must now look at you and our customers and advise you of your legal obligations. We have included links below which are clear and informative, helping you understand your legal duties. Please do take some time to familiarise yourselves with these, we are trying to keep you informed and compliant.

Therefore, if you are a business and use, or intend to use, any of the ‘Regulated Substances’ we require the attached statement to be signed and returned with a form of ID which is available here at https://www.advanced-water.co.uk/pdf/form-for-customers-the-control-of-explosives-precursors-and-poisons-regulations-2023.pdf

Validity: the statement will be valid for 12 months from date completed, or if the designated signatory changes we will require an updated statement. We will review this statement during the Annual contract review that is undertaken with your Account Manager. The outline list of products affected by this legislation is shown here at https://www.advanced-water.co.uk/pdf/product-list-control-of-explosives-precursors-and-poisons-regulations-2023.pdf

Please complete and send form and proof of identification to info@advanced-water.co.uk.co.uk by 30th September 2023.

#Legionella #Training #AWT

AWT Training course on 16th November 2023 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

#Legionella #Training #AWT

AWT Training course on 5th October 2023 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring hot and cold systems to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

#Legionella #Training #AWT

Advanced Water Technologies have partnered with a Rail Maintenance Company and have successfully had a number of Service Technicians complete and pass their Personal Trackside Safety Training course. This now enables AWT Staff to work on Trackside Facilities, as required, to support and deliver services on behalf of the partner company maintaining water systems.

#Legionella #Training #AWT

AWT Training course on 21st September 2023 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

#Legionella #Training #AWT

Advanced Water Technologies Ltd continued growth and success with 3 very positive acquisitions that have been completed in the past 3 months.

Advanced Water Technologies are pleased that they have been able to acquire DMAC Water Services through which it will continue to deliver services to a broad range of clients nationally, Pennine Water brings in a number of national clients and an ability to improve upon a number of services offered already, and finally the acquisition of CERTIFACT, a southern based water treatment company that will allow AWT to build upon its present successes in the South, South East and West, and home counties. Providing the AWT Southern Team with a base and support of a dedicated team of support staff. All 3 acquisitions confirm that Advanced Water Technologies ltd are a growing force within the industry, specializing in Water Treatment and all ACOPL8 services.

The Managing Director of AWT, Peter Barratt, welcomes those staff who have joined us through these acquisitions and is “looking forward to working with each and everyone of you”.

#AWT #Growth #Success

AWT Training course on 6th June 2023 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents.

On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

#Legionella #Training #AWT

Advanced Water Technologies have worked with their partners to ensure a smooth project has been completed within an assisted living complex, replacing a leaking sectional cold water storage tank for a new one.

Receiving praise from the client on how the project ran from start to finish with minimal disruption, polite and courteous service from the team. A job well done.

#Legionella #Training #AWT

AWT Training course on 18th May 2023 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents. On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

#Legionella #Training #AWT

AWT Training course on 20th April 2023 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring hot and cold systems to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?

This course is designed to raise awareness and reduce the risk associated with the waterborne bacteria that cause Legionnaires’ Disease. Delegates who attend this course will leave with an understanding of how to apply relevant legislation within their day-to-day duties, with a particular focus on the Health and Safety Executive’s Approved Code of Practice L8 and accompanying Technical Guidance HSG 274 documents. On the completion of the course candidates will:

Course duration and accreditation:

This is a one-day course. Successful delegates will achieve a formal Level 2 qualification awarded by Highfield Qualifications Ltd. The qualification is accredited by Ofqual (the Qualifications and Examinations regulator for England and Northern Ireland) and sits on the Regulated Qualifications Framework (RQF).

#Legionella #Training #AWT

AWT Training course on 7th March 2023 at our training academy next door to Junction 30 on the M1 in Barlborough, Derbyshire. More details can be found at https://www.advanced-water.co.uk/training-academy or to confirm your booking please contact us at training@advanced-water.co.uk.

Is this course for you or your staff?

This Ofqual accredited course is aimed at staff involved in managing, supervising, and monitoring cooling towers and evaporative condensers to ensure the risk presented by Legionella bacteria is minimised and compliance is achieved.

Why should I attend?