Advanced Water

A company overview

EnquiriesWithout effective Pre-Treatment equipment and chemistry your finished goods will look and perform below standard.

This is true for either Metal, Plastic or Composite components and if untreated or sub standardly treated the nett finished goods results in:

These factors reduce your competitiveness and quality within your market, so reducing customer retention and standing within your market sector.

Call our experienced team on:

At Advanced Water Technologies we want to keep you informed and we want to make sure that you have access to all the information you need. You can view all of our accreditations, find out about our services and view important links and legislation information. You can also call or email us by visiting our contact us page.

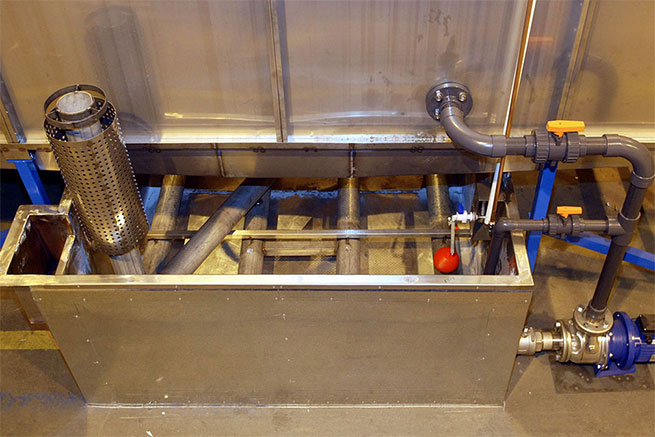

At Advanced Water Technologies, we have developed a comprehensive Finishing treatment range of chemicals for effective management, improved performance and reduced environmental impact, whilst keeping your system operating safely and efficiently.

These chemicals can be split into three distinct categories:

And because we are compliant with the latest legislation and regulations, particularly in the areas of health, safety and the environment, you can be sure that the solution we deliver will be high quality, reliable, cost effective and tailored to meet your exact requirements.

Chemicals we use in our pre-treatment plants and paint booths treatment:

Why do you need a paint booth treatment?

If left untreated, paint sludge from your paint booth system creates a contaminated and unhygienic problem which can:

These factors reduce efficiency, put your system at risk, shorten plant life, create costly down time and waste energy, chemicals and water charges. Spray booth systems are also excellent breeding grounds for many types of biological growth. Left untreated, bacterial and fungal slimes can lead to high risks from Legionnaires’ disease and booth odour problems.

At Advanced Water Technologies, we have developed a comprehensive paint booth treatment programme for effective management, improved performance and to keep your system operating safely and efficiently.

These services include:

And because we are compliant with the latest legislation and regulations, particularly in the areas of health, safety and the environment, you can be sure that the solution we deliver will be high quality, reliable, cost effective and tailored to meet your exact requirements. A document with more information about our services can be downloaded below.

© Advanced Water Technologies